OSHA Compliance

OSHA Requirements for Hydraulic Tools

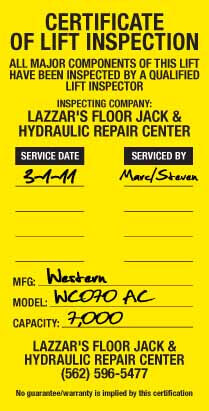

OSHA Required - 1. Every 6 months all hydraulic tools must be serviced.

OSHA Required - 2. The manufacturer's rated capacity MUST be legibly marked on all jacks.

OSHA Required - 3. Locking mechanism must be attached to unit. ie: Pin by steel cable.

Lazzar's Hydraulics keeps you OSHA compliant. We make capacity stickers that are water and oil resistant. A Lazzar service technician can visit your facility or we can ship the labels to you for self implementation. If Lazzar's is hired to implement this requirement, the steps taken are.

- We pick up the units and bring them back to our shop.

- Complete cleaning and inspection of product.

- Repair if necessary and fully lubricate unit.

- Load test unit to manufactures specifications.

- Apply approved capacity sticker.

- Deliver back to customer.

All items below, come straight from the OSHA.GOV compliance website.

Hydraulic Power Tools

The fluid used in hydraulic power tools must be an approved fire-resistant fluid and must retain its operating characteristics at the most extreme temperatures to which it will be exposed. The exception to fire-resistant fluid involves all hydraulic fluids used for the insulated sections of derrick trucks, aerial lifts, and hydraulic tools that are used on or around energized lines. This hydraulic fluid shall be of the insulating type.

The manufacturer's recommended safe operating pressure for hoses, valves, pipes, filters, and other fittings must not be exceeded.

All jacks — including lever and ratchet jacks, screw jacks, and hydraulic jacks — must have a stop indicator, and the stop limit must not be exceeded. Also, the manufacturer's load limit must be permanently marked in a prominent place on the jack, and the load limit must not be exceeded.

A jack should never be used to support a lifted load. Once the load has been lifted, it must immediately be blocked up. Put a block under the base of the jack when the foundation is not firm, and place a block between the jack cap and load if the cap might slip.

To set up a jack, make certain of the following:

- The base of the jack rests on a firm, level surface;

- The jack is correctly centered;

- The jack head bears against a level surface; and

- The lift force is applied evenly.

Proper maintenance of jacks is essential for safety. All jacks must be lubricated regularly. In addition, each jack must be inspected according to the following schedule: (1) for jacks used continuously or intermittently at one site — inspected at least once every 6 months, (2) for jacks sent out of the shop for special work — inspected when sent out and inspected when returned, and (3) for jacks subjected to abnormal loads or shock — inspected before use and immediately thereafter.