Repair Services - Hardfacing

At this time we're no longer offering repairs.

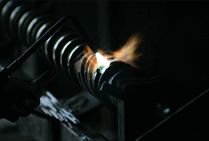

Lazzar's hydraulics provides Hardfacing services to meet your job requirements. Hardfacing is a metal working process where a more durable and stronger material is applied to the base metal component. This process is generally applied via ARC Welding. Powder Metal Alloys or Plasma Transfer Arc welding is also used.

Metal parts fail most often because they wear, which causes them to lose dimension and functionality. Hardfacing or hard surfacing builds up weld metals on the surface of the components. Carbon and low Alloy steel with carbon contents of less than 1% can be hardfaced. High carbon alloys may require a special buffer layer. Hard facing can be applied to Stainless Steel, Manganese steels, cast iron, nickel based alloys and those of Copper.

Hard facing can be applied to a worn surface, be it from corrosion, erosion, fretting, fatigue or abrasion, in order to restore it and to increase its wear resistance thus increasing the surface life of components that are utilized in a dynamic and high stress environment. The process can also be implemented into a maintenance or upgrade program instead of buying new components at much greater cost savings to your company. This results in much less downtime and reduced operating costs in your production line or work process. Simply by changing the hard facing alloy a component can exhibit an extended as much as 30 times the extended life.

Different hard facing materials can be applied depending on your requirements and the components working environment, these can be applied thru Gas Metal Arc Welding, Electrolag Welding and Plasma Arc Welding to name but a few. Lazzar Hydraulics most often utilizes Colmonoy #56, a premium alloy which is nickel based and exhibits superior wear resistance, resistant to heat corrosion and galling.

Lazzar Hydraulics can provide hardfacing services for all your requirements.