Identify Seals

HCRC carries standard O-Rings, U-Seals, Quad Rings and Wipers. All standard and metric sizes available.

|

Click to enlarge

Click to enlarge

|

O-Rings |

|

Click to enlarge

Click to enlarge

|

Symmetrical U-Seal

|

|

Click to enlarge

Click to enlarge

|

Rod U-Seal

|

|

Click to enlarge

Click to enlarge

|

Piston U-Seal

|

|

Click to enlarge

Click to enlarge

|

Loaded U-seals

|

|

Click to enlarge

Click to enlarge

|

Quad Rings |

|

Click to enlarge

Click to enlarge

|

D Wipers |

|

Click to enlarge

Click to enlarge

|

Double lip oil seals

|

|

Click to enlarge

Click to enlarge

|

Single lip oil seals

|

|

Click to enlarge

Click to enlarge

|

Female Adapters

|

|

Click to enlarge

Click to enlarge

|

Center (Vee) Ring

|

|

Click to enlarge

Click to enlarge

|

Male Adapters

|

|

Click to enlarge

Click to enlarge

|

Vee Packing Sets

|

Seals Info

Originally hydraulic seals were made of leather and rope. These are still being used, but today mostly Buna-N and urethane are the material of choice. O rings and Quad rings can be made of Buna-N or Nitrile, Viton, EPDM, Silicone, and Teflon. Other materials are also available.

|

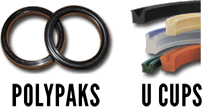

U Cups and Polypaks are used mostly inside the main cylinder as a rod or shaft seal. These are mostly urethane. A Polypak is a type of U cup with a O ring or a Quad ring stuffed in the center of it. CHEVRON Seals, are the most durable seals for hydraulic applications but have been mostly replaced with URETHANE U-CUPS and POLYPAK. |

|

PACKING Gland, can be rope or reinforced neoprene. Primarily used for rod wipers. A Jack that uses rope or packing gland will have an adjustable gland nut that allows users to tighten every so often to adjust for wear. |

Buna (aka NBR, Nitrile) is the standard in hydraulic and pneumatic sealing elastomers. Its oil resistant nature makes it the top choice of materials being used with petroleum based hydraulic fluids. Buna has a good abrasion resistance, high tensile strength and resistance to compression set.

- Color: Black

- Temperature Min: -40°F

- Temperature Max: 250°F

Fluoroelastomer (aka Viton®, FKM, fluorocarbon elastomer) seals are widely used in applications dealing with extreme temperature and/or extreme chemicals. Its compatibility to nearly all chemicals (exception - Skydrol, certain esters and ethers) makes it a popular elastomer in chemical processing, paper and pulp mills, various other chemical applications. Note - Viton® is a registered trademark of DuPont Performance Elastomers.

- Color: Black or Brown

- Temperature Min: -15°F

- Temperature Max: 400°F

Silicone compounds are generally not recommended for dynamic sealing applications due to poor tensile strength and abrasion resistance. Silicone does exhibit excellent resistance to extreme temperature and is an acceptable FDA material. Typical use for silicone is in dry heat applications and food processing applications.

- Color: Red

- Temperature Min: -65°F

- Temperature Max: 450°F

ERP (aka EPDM, Ethylene Propylene) is used in applications that deal with acids, weak alkalis, and automotive break fluid. EPR is also an acceptable FDA material.

- Color: Black

- Temperature Min: -65°F

- Temperature Max: 300°F

Neoprene is resistant to ammonia, freon, oxygen, ozone and many other fluids. An excellent material for use in pump and refrigeration applications.

- Color: Black

- Temperature Min: -65°F

- Temperature Max: 300°F

Fabric is a composite material made by binding a cotton duck material with an elastomer such as Buna or Fluoroelastomer. The result is a stiff material with a high tensile strength. Fabric is used widely in hydraulic applications.

- Color: Black

- Temperature Min: Varies

- Temperature Max: Varies

Teflon (aka PTFE, TFE) can be used in applications with extreme temperatures, extreme pressures and extreme chemicals. Since Teflon has a tendency to cold flow and has no memory, it is often filled with other materials (glass, bronze, and nickel) before it is used to make piston seals, rod seals and wipers. Note - Teflon is a registered trademark of duPont de Nemours and Company.

- Color: White

- Temperature Min: -200°F

- Temperature Max: 500°F

Polyurethane (aka Hythane, Garthane) makes an excellent choice for hydraulic systems due to its good temperature range and high abrasion resistance. Urethanes are highly resistant to petroleum oils, hydrocarbon fuels, oxygen, ozone, and weathering.

- Color: Clear, Black, Blue, Green, Red

- Temperature Min: -50°F

- Temperature Max: 200°F

Polymyte is an elastoplastic material with exceptionally high tear strength. Its high durometer makes it suitable for applications where extrusion is a problem. Polymyte can be used with petroleum based fluids, water based fluids, phosphate ester fluids, some chlorinated fluids and many solvents.

- Color: Orange

- Temperature Min: -500°F

- Temperature Max: 2750°F

Fluromyte is a material that exhibits high tear strength and abrasion resistance and is preferred over Polymyte in high friction applications. Fluromyte has an excellent resistance to ozone, oxygen, petroleum and phosphate ester based fluids.

- Color: Purple

- Temperature Min: -65°F

- Temperature Max: 300°F

Click here for information on how to measure seals.